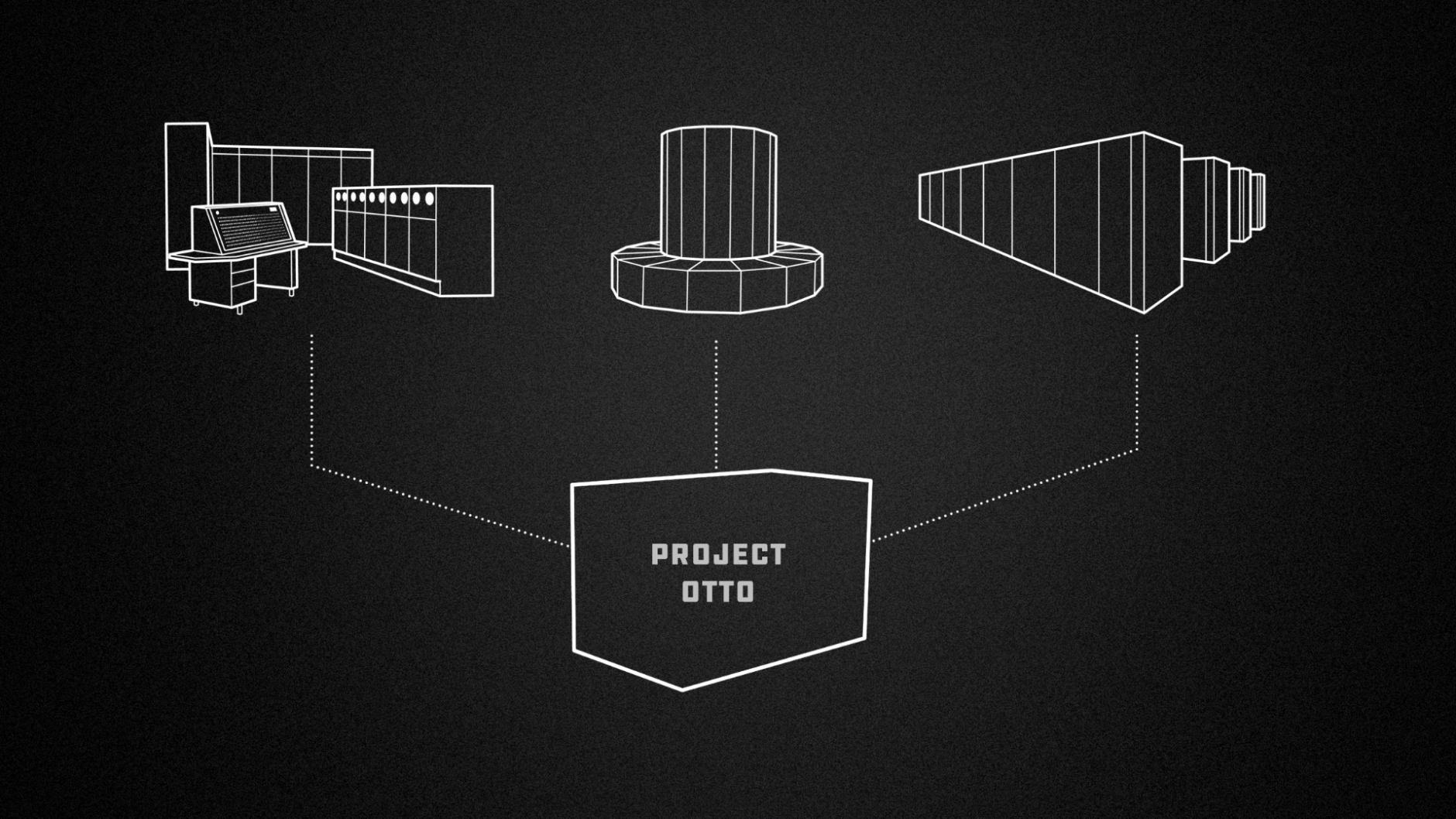

Two-phase liquid immersion cooling enables supercomputers to squeeze more computing power into smaller footprints. The TMGcore system loads PC boards packed with heat-generating processors into liquid filled bays using a robotic handling system. All of this is controlled remotely with sophisticated software through an intuitive user interface. Our team defined the brand, shaped the look, designed the experience and helped engineer these products through to production.

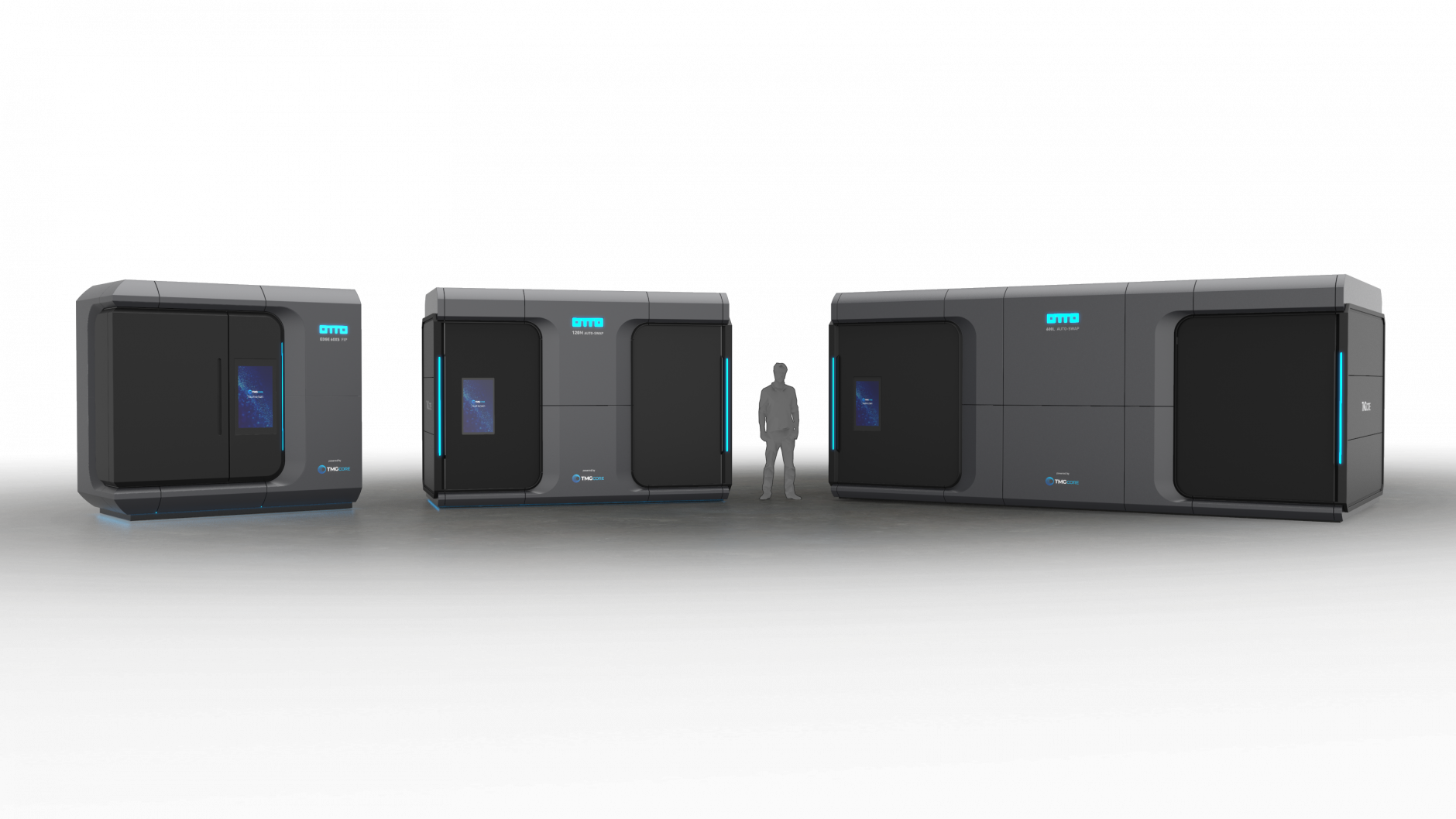

New Category - Bold Vision

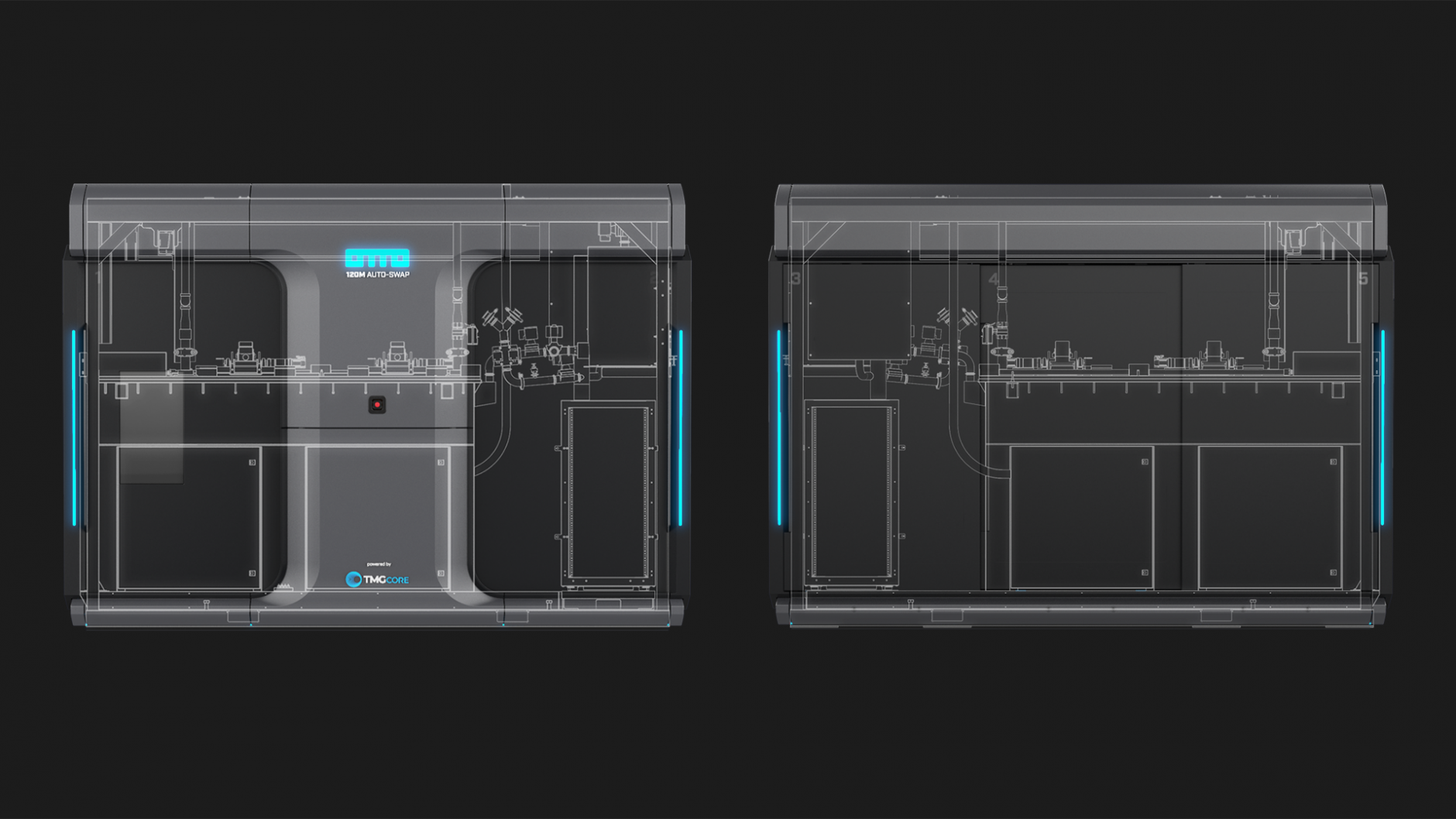

Our Industrial Design and brand development team were challenged to create an iconic look for an entirely new category of products. Studies of the historic development of supercomputers and current trends led us to a family design language that could be applied across all the TMGcore products.

Usability First

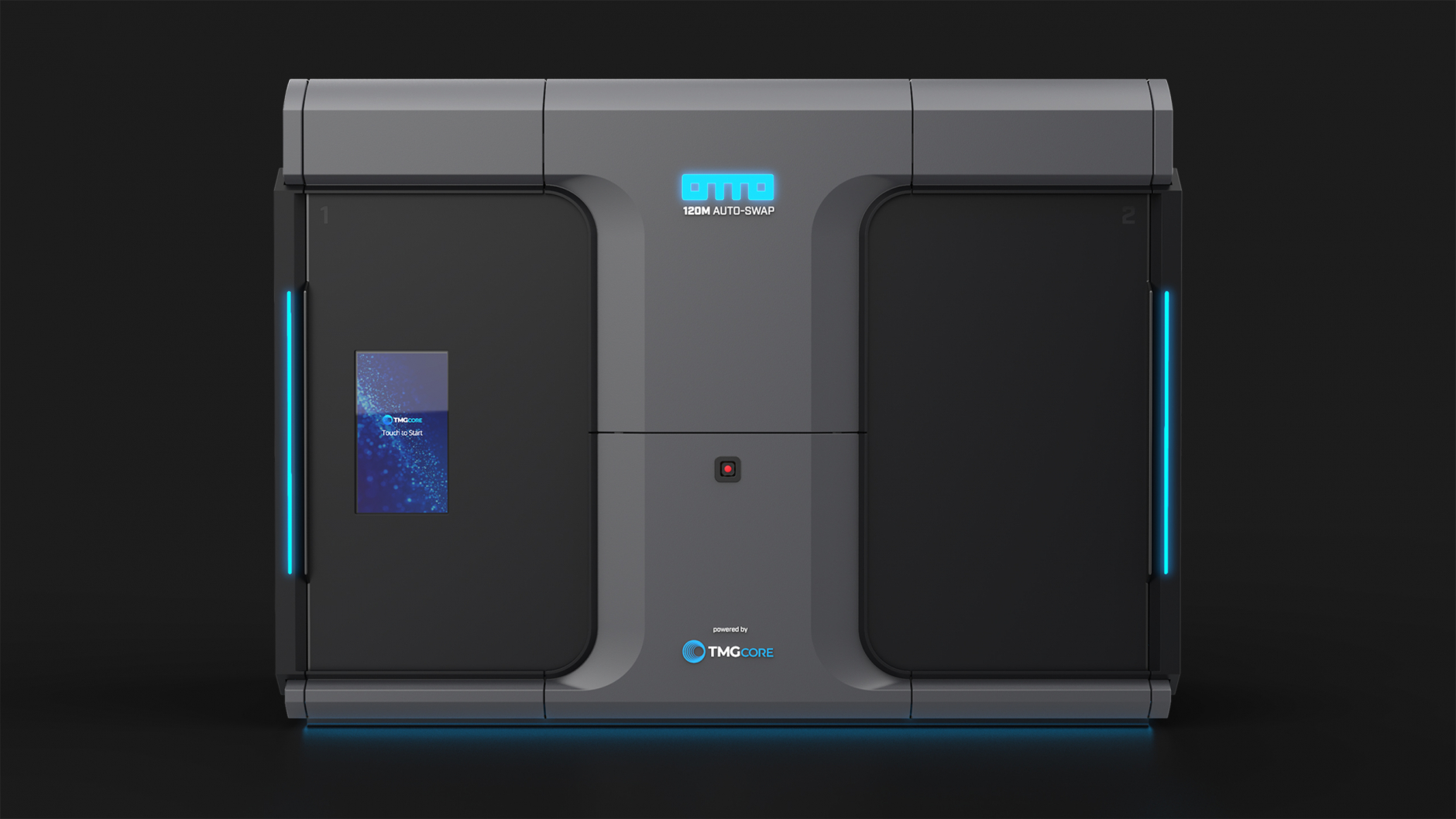

Our User Experience team had to consider both the physical challenge of interacting with these room-sized machines and also their digital computer interfaces. We defined the physical system architecture and an access scheme to allow servicing and troubleshooting. We also engineered a modular exterior skin of fire-rated pressure-formed panels

Human Machine Interface

The digital User Interface (UI) of the devices was designed to look and feel the same on the machine touchscreen as it does on remote PCs, tablets and smartphones. The UI design layers information in order of its hierarchy showing need-to-know data all the time and finer details in a consistent and accessible format.

Loading and Unloading

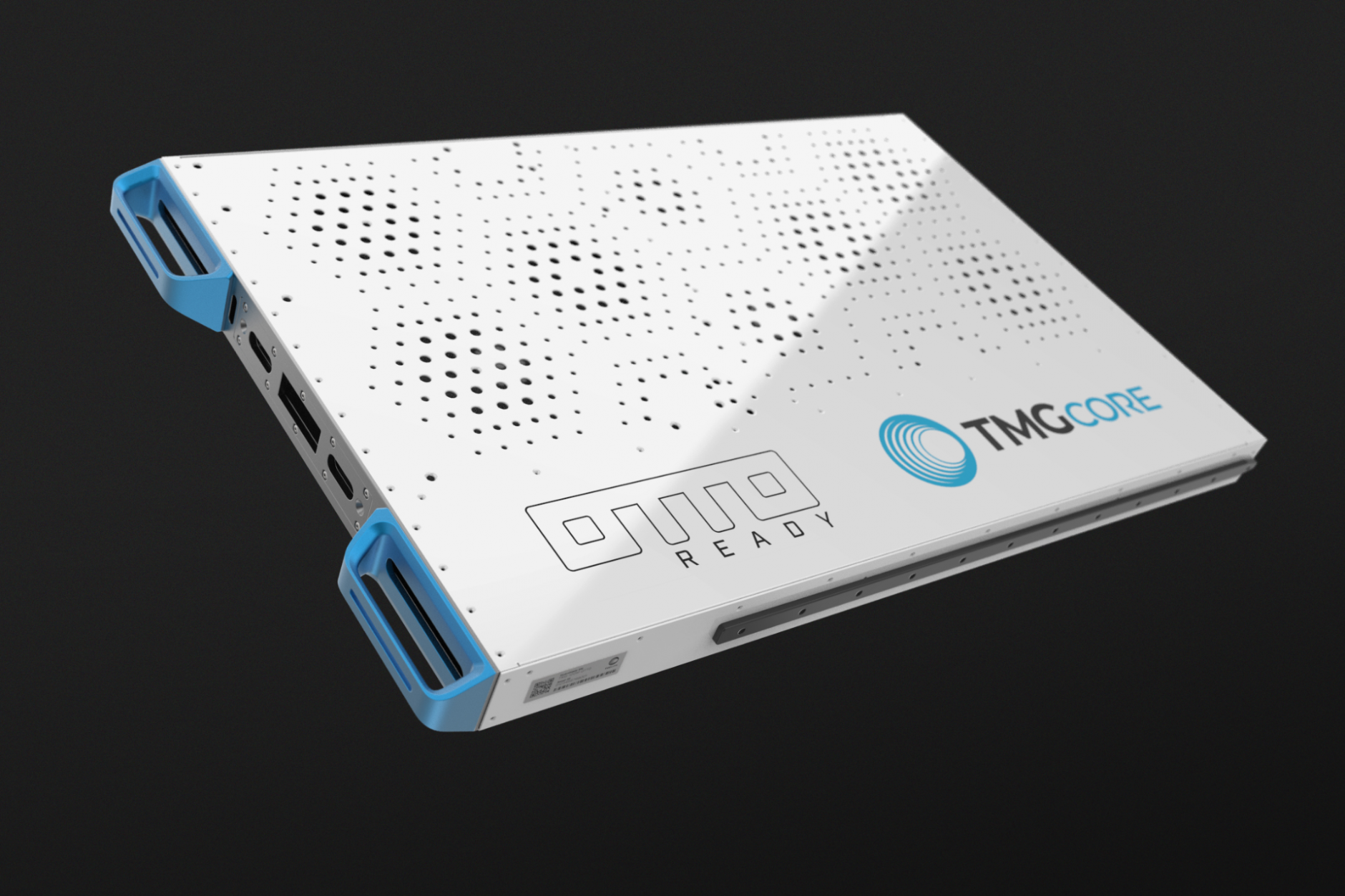

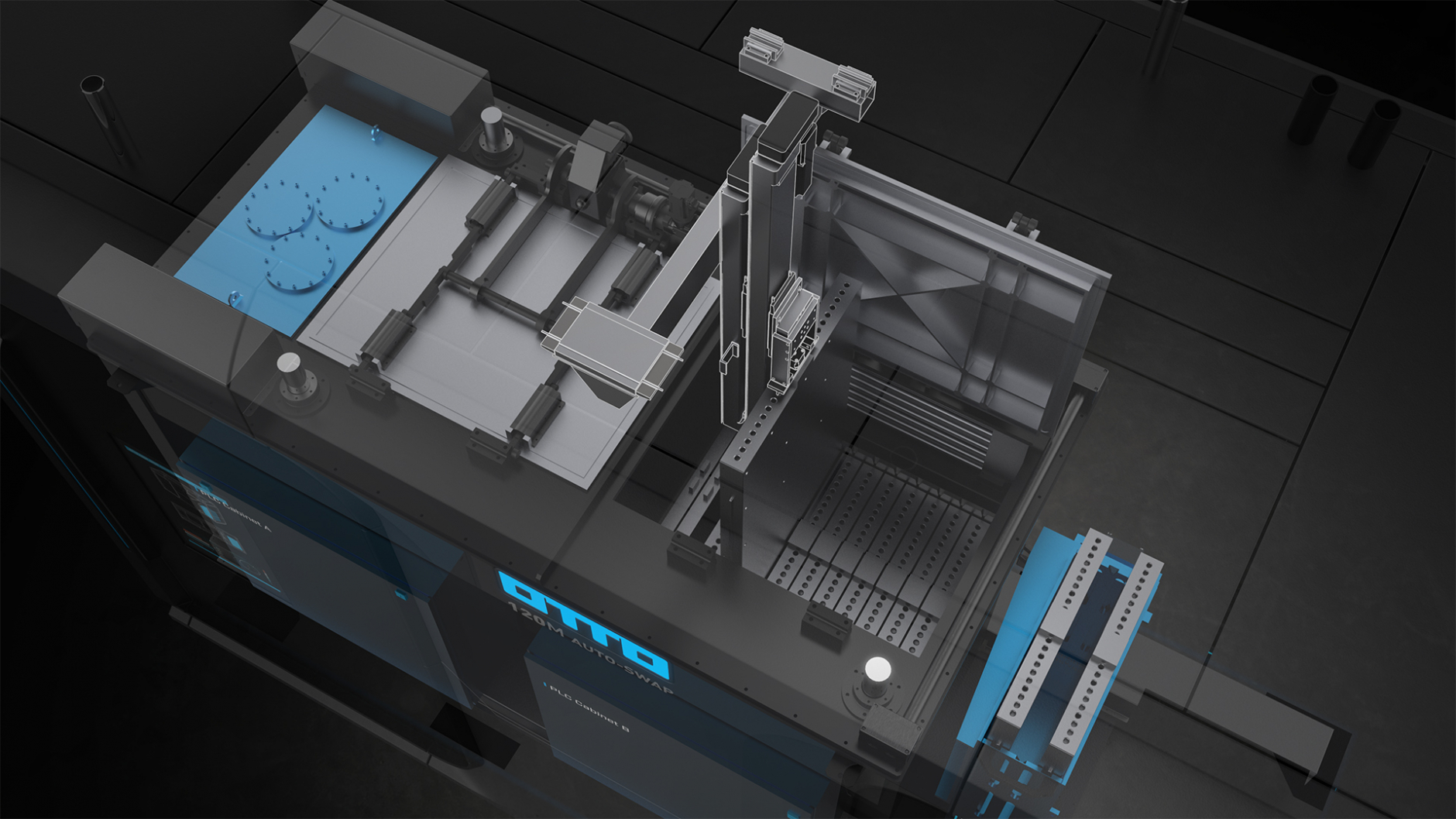

The custom built computer boards weigh as much as 100 pounds. Mixer designed a modular blade that could house different PC board form-factors for docking inside the liquid cooling chamber. A unique rotating transfer system was engineered by our team to allow technicians to handle these blades with minimal human effort.

Consider Every Touchpoint

The interaction with all the touchpoints of the machine was very important. Every inch of the machine, from the look of the blades to the safety labels, was considered to express a strong visual statement of TMGcore’s value proposition.